Superior Surface Finishes

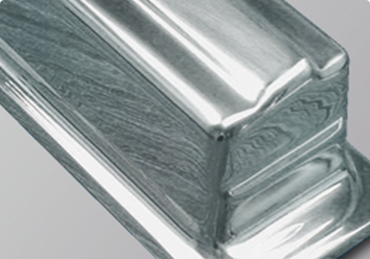

Aluminum Castings with Exceptional Surface Quality

Aluminum castings need to perform at the highest level while looking exceptional too. We achieve both with our specialized green sand molding process using oil-bonded Petro Bond sand. This process delivers consistent mold compactability, creating smoother, more reliable surfaces. Across the industry, Petro Bond stands out for producing casting finishes superior to many other methods.

Advantages of Superior Surface Finishes

With Petro Bond, you get more than just a clean finish, you get dependable results every time. Our process provides:

- Consistent mold compactability for smooth surfaces

- Surface finishes superior to many other casting methods

- Reliable quality across both small and large production runs

Where Premium Finishes Make a Difference

With exceptional surface quality, your castings don’t just perform well, they elevate your products. That’s why aluminum castings with premium finishes are ideal for:

- Laboratory equipment

- Aesthetic external parts

- Enclosures and housings

- Hand tools

- Cookware and covers

- High-profile parts where appearance matters

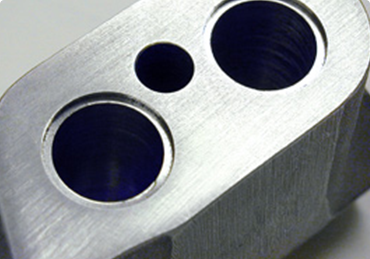

Best Surface Finishes for Secondary Coatings

With a smooth, consistent surface, your parts are ready for any finishing touch. Our castings provide the perfect foundation for:

- Powder coating

- Anodizing

- Plating (including zinc and specialty coatings)

- Traditional wet painting

Why Choose Olson Aluminum for Superior Surface Finishes?

Backed by decades of expertise, Olson Aluminum offers distinct advantages in casting aesthetics, including:

- Superior Petro Bond process for consistent results

- Castings that both look good and perform better

- Proven reliability for industries requiring visual quality

- Flexible production capabilities for projects of any scale

Frequently Asked Questions

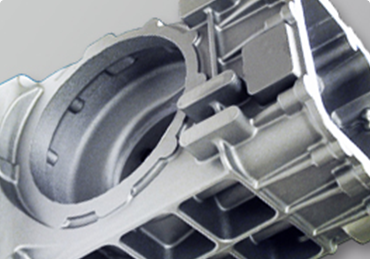

What is Air Set Molding in aluminum casting?

Air Set Molding is a process that uses chemically bonded sand molds, allowing for more intricate designs, deeper draws, and greater dimensional accuracy compared to green sand molding.

What types of projects are best suited for Air Set Molding?

Air Set Molding is ideal for larger castings, complex geometries, and detailed features that cannot be achieved with traditional green sand processes.

How does Air Set Molding improve production flexibility?

With versatile tooling options, Air Set Molding supports both low-volume runs (a few parts) and high-volume production (tens of thousands of castings).

What industries benefit from Air Set Molding?

This process is widely used in aerospace, automotive, industrial machinery, and energy sectors, where precision and strength are critical.

Does Olson Aluminum offer finishing and heat treatment in-house?

Yes, we provide in-house heat treatment services, ensuring quality control and faster delivery without relying on third-party vendors.

Ready to Get Started?

Olson Aluminum Castings is committed to delivering high-quality aluminum castings that meet your design, performance, and production needs. Whether you need prototypes, pressure-tight castings, superior finishes, or high-machinability parts, our team is here to help you succeed. Contact us today at 815-229-3292 to discuss your project and discover how we can deliver the right solution for you!