Air Set Molding

The addition of our new Air Set Molding line along with the additional in-house heat treat facilities has greatly increased the overall capacity of our foundry, virtually doubling our output capability as we position our casting program for future growth. This foresight has provided us with unparalleled ability to provide industry short lead times while continuing to achieve a consistent “on time delivery” of over 98.5%.

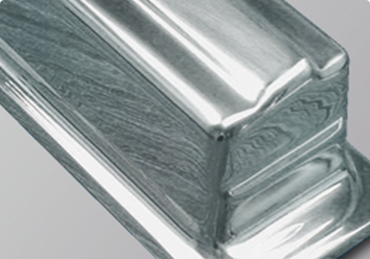

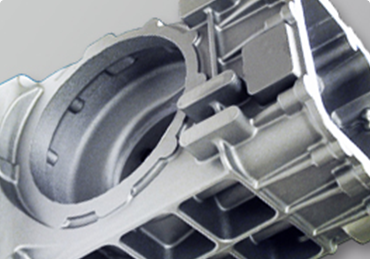

Air Set Molding compliments our current green sand foundry capacity by offering significant advantages in aluminum casting production providing opportunities to produce larger and more challenging casting designs with deeper draws and improved detail. Additionally, Air Set molding offers flexible tooling options bringing an added measure of economy to a broad range of production runs, many as low as several castings or well into tens of thousands.

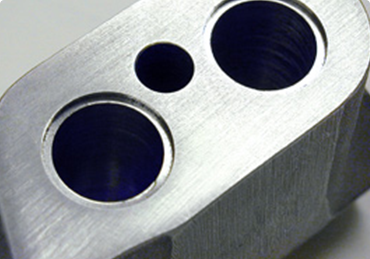

Along with the ability to produce ever more intricate cast profiles with deeper draws and minimal draft, our Air Set Molding Line provides the same internal casting integrity traditionally provided by Olson Aluminum Castings. Specifically we provide castings with exceptional machining characteristics, free from voidsand detrimental porosity along with superior surface finishes

Air Set Molding compliments our current green sand foundry capacity by offering significant advantages in aluminum casting production providing opportunities to produce larger and more challenging casting designs with deeper draws and improved detail. Additionally, Air Set molding offers flexible tooling options bringing an added measure of economy to a broad range of production runs, many as low as several castings or well into tens of thousands.