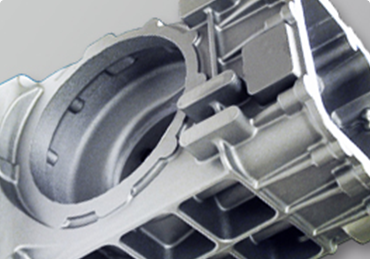

Pressure Tight & Leak Free Castings

Precision Aluminum Casting with Pressure-Tight Integrity

Pressure-tight and leak-free castings are critical in industries where performance and safety cannot be compromised. Through our proprietary alloy cleansing and degassing techniques, we eliminate harmful contaminants that cause hard spots, shrinkage, porosity, and substandard physical properties. Olson Aluminum Castings consistently delivers components with the highest level of integrity and reliability.

Advantages of Pressure-Tight Castings

With our casting process, you get the performance and reliability your parts demand, including:

- Proven leak-free integrity under demanding conditions

- Defect-free castings through the elimination of porosity, shrinkage, and voids

- Refined grain structure for strength and durability

- Consistent quality with improved chemical property control

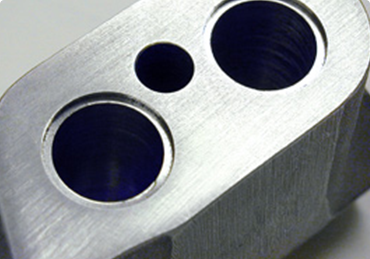

Superior Casting Quality & Reliability

Every casting we produce is engineered for maximum performance. By maintaining strict chemical property limits, using specialized additives, and designing optimized gate and riser systems, we prevent internal shrinkage and deliver castings with unmatched integrity.

Why Choose Olson Aluminum for Pressure-Tight Castings?

Backed by decades of expertise, Olson Aluminum offers distinct advantages in pressure-tight aluminum casting, including:

- Proprietary processes for alloy cleansing and degassing

- Consistently leak-free and defect-free castings

- Experience serving hydraulic, pneumatic, and fluid control industries

- Proven success in meeting the strictest industry standards

Frequently Asked Questions

What makes a casting pressure tight?

A pressure-tight casting maintains structural integrity under specified fluid or gas pressure without leaking.

How does Olson Aluminum ensure leak-free castings?

We use proprietary cleansing, degassing, and gating techniques to eliminate porosity, shrinkage, and contamination.

What industries benefit most from pressure-tight castings?

Industries such as hydraulics, pneumatics, fuel systems, and pumps rely on leak-free castings for performance and safety.

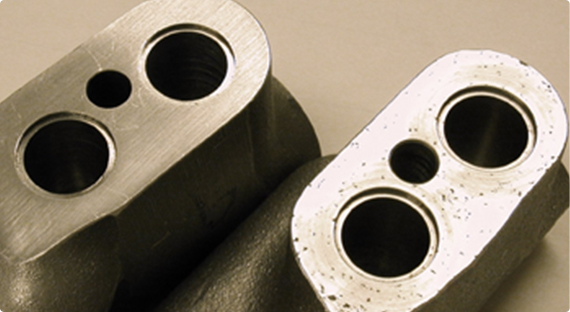

What problems occur with low-integrity castings?

Defects like porosity, shrinkage, and gas pockets can cause leaks, reduce strength, and compromise service life.

Can Olson Aluminum handle high-volume production?

Yes, we can support small runs or large-scale projects with the same commitment to quality.

Ready to Get Started?

Olson Aluminum Castings is committed to delivering high-quality aluminum castings that meet your design, performance, and production needs. Whether you need prototypes, pressure-tight castings, superior finishes, or high-machinability parts, our team is here to help you succeed. Contact us today at 815-229-3292 to discuss your project and discover how we can deliver the right solution for you!