Air Set Molding

Precision Aluminum Casting with Air Set Molding

Air Set Molding at Olson Aluminum Castings gives you stronger, more precise parts, without the long wait. This advanced process makes it possible to achieve deeper draws, sharper details, and flexible production runs. With our in-house heat treatment and expanded molding line, we’ve nearly doubled capacity, allowing us to take on complex designs, deliver faster, and maintain a 98.5% on-time delivery rate.

Advantages of Air Set Molding

Air Set Molding complements our existing green sand foundry and offers unique benefits in aluminum casting production, including:

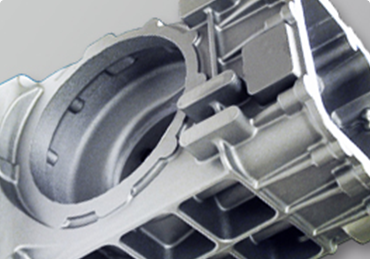

- Ability to produce larger and more complex castings

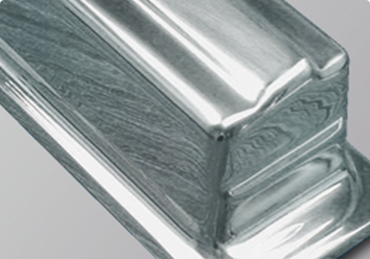

- Exceptional detail with deeper draws and improved definition

- Flexible tooling options for both short-run and high-volume production

- Cost-effective solutions for runs ranging from just a few castings to tens of thousands

Superior Casting Quality & Integrity

With Air Set Molding, we produce castings that not only meet complex design requirements but also maintain the internal integrity and durability our customers rely on. Key quality features include:

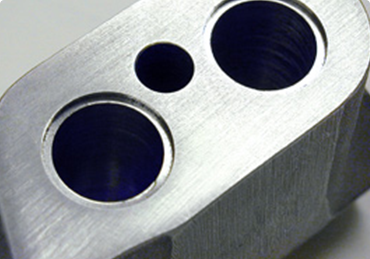

- Excellent machining characteristics

- Castings free from voids and detrimental porosity

- Superior surface finishes for aesthetic and functional applications

Why Choose Olson Aluminum for Air Set Molding?

Backed by decades of expertise, Olson Aluminum offers distinct advantages in Air Set Molding, including:

- Nearly doubled foundry capacity for faster turnaround times

- Proven delivery performance of 98.5% on-time

- Decades of experience producing high-quality aluminum castings

- Ability to handle projects of any size or complexity

Frequently Asked Questions

What is Air Set Molding in aluminum casting?

Air Set Molding is a process that uses chemically bonded sand molds, allowing for more intricate designs, deeper draws, and greater dimensional accuracy compared to green sand molding.

What types of projects are best suited for Air Set Molding?

Air Set Molding is ideal for larger castings, complex geometries, and detailed features that cannot be achieved with traditional green sand processes.

How does Air Set Molding improve production flexibility?

With versatile tooling options, Air Set Molding supports both low-volume runs (a few parts) and high-volume production (tens of thousands of castings).

What industries benefit from Air Set Molding?

This process is widely used in aerospace, automotive, industrial machinery, and energy sectors, where precision and strength are critical.

Does Olson Aluminum offer finishing and heat treatment in-house?

Yes, we provide in-house heat treatment services, ensuring quality control and faster delivery without relying on third-party vendors.

Ready to Get Started?

Olson Aluminum Castings is committed to delivering high-quality aluminum castings that meet your design, performance, and production needs. Whether you need prototypes, pressure-tight castings, superior finishes, or high-machinability parts, our team is here to help you succeed. Contact us today at 815-229-3292 to discuss your project and discover how we can deliver the right solution for you!